OXIDATION DITCH

Description of Oxidation Ditch

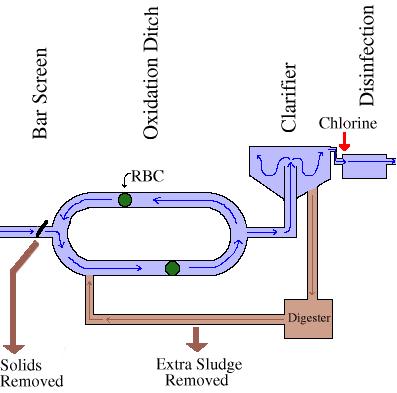

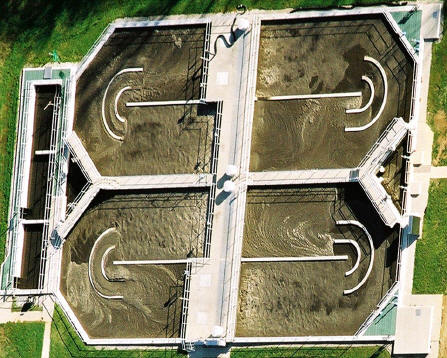

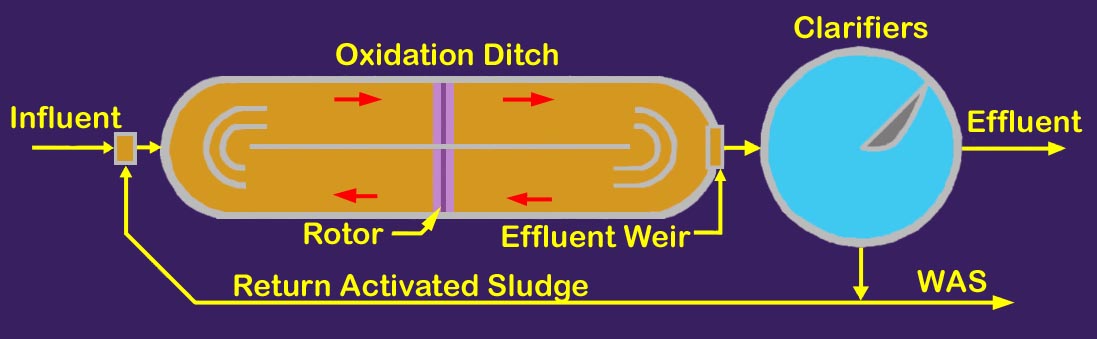

Oxidation ditch is an extended aeration activated sludge process. An oxidation ditch is a large holding tank in a continuous ditch with oval shape similar to that of a racetrack. The ditch is built on the surface of the ground and is lined with an impermeable lining. This allows the waste water to have plenty of exposure to the open air for the diffusion of oxygen. The liquid depth in the ditches is very shallow, 0.9 to 1.5 m, which helps to prevent anaerobic conditions from occurring at the bottom of the ditch. The oxidation ditch effluent is clarified in a secondary clarifier and the settled sludge is returned to maintain a desirable MLSS concentration. The MLSS concentration in the oxidation ditch generally ranges from 3,000 mg/ L to 5,000 mg/ L; however, this is dependent upon the surface area provided for sedimentation, the rate of sludge return, and the aeration process.

Longer retention time within the ditch will allow for a greater amount of organic matter to be broken down by the aerobic bacteria. After treatment, the waste water is pumped to a secondary settling tank where the sludge and the water are allowed to separate. From there the effluent goes on to other treatment processes or disposal.

The sludge that has accumulated on the bottom of the secondary settling tank is then removed and a portion of it is returned to the ditch to facilitate microbial activity in the next batch of sewage to be treated. The oxidation ditch can be operated on continuous basis also

3 Responses to “OXIDATION DITCH”

Leave a Reply

LIKE TO GET UPDATES

LIKE TO GET UPDATES  TO GET EXPERT GUIDE

TO GET EXPERT GUIDE

Excellent, I discovered a lot of information in sewage treatment.

Looking for an experience suppliers and vendors for this technology (Oxidation Ditch Sewage Treatment Plants with 8000m3/day).

Best Regards,

Al-Sifao

Would ypu please provide me a diffrences between a Ditch Oxidation , Activated Sludge , Extended Oxidation .

The Best,

Ibrahim Gibara

Zuara , Libya